Présentation

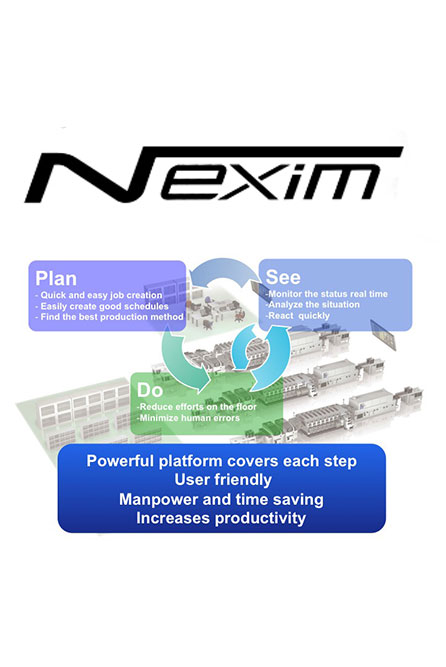

Creating program data is very easy with Nexim and production schedules can be created automatically. Instructions for checking out parts and performing changeover are issued based on these created schedules and part resupply instructions are issued matching the machine operating conditions.

For this, production is performed by connecting the stages with data using Nexim.